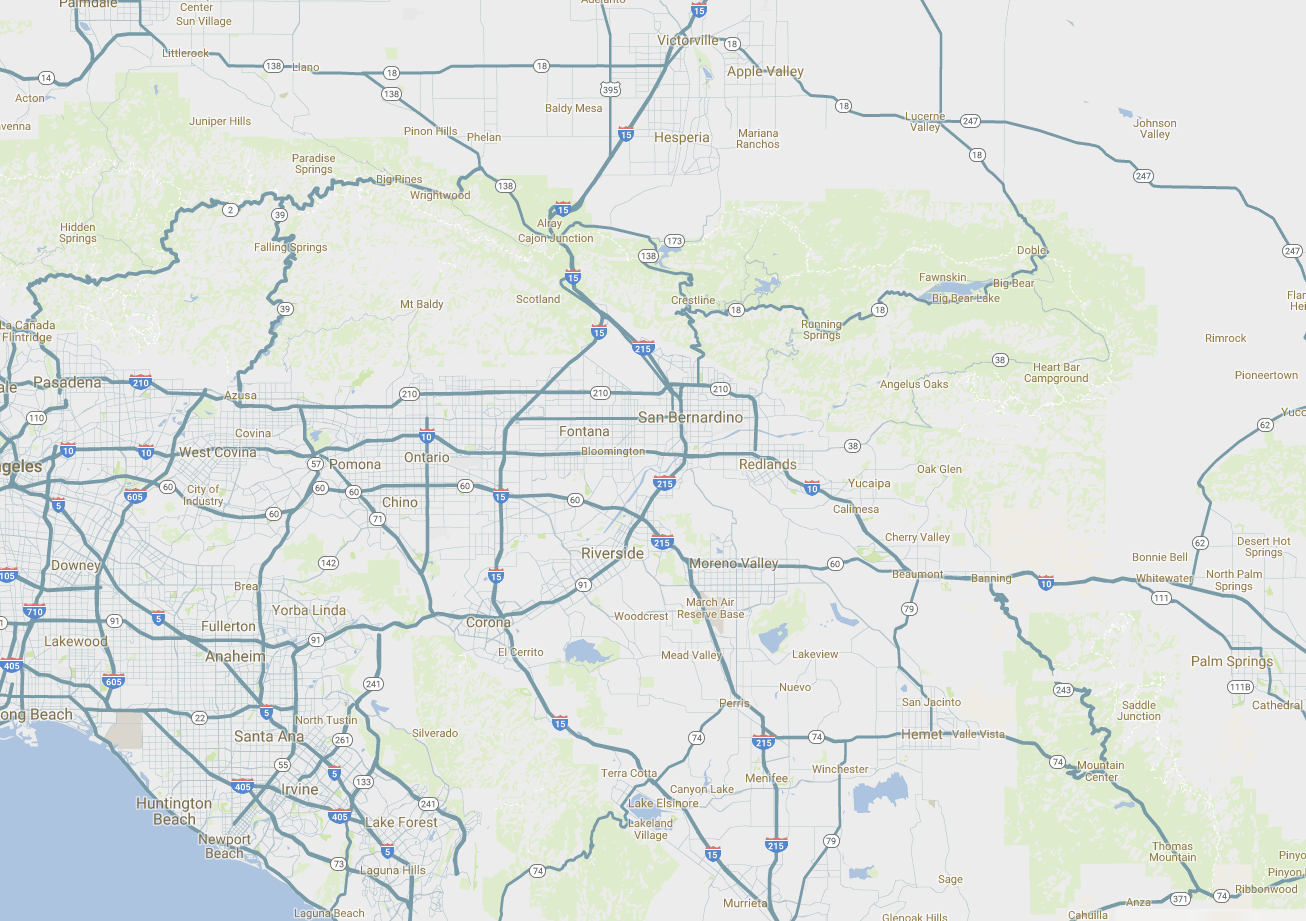

CHOOSE A HEATING OR COOLING SERVICE

At Burgeson's, we put our customers first. When you choose us, we make sure you get the highest quality heating and cooling repairs and installations in the area. In fact, all of our technicians undergo our unique, in-house training where they learn how to serve you the right way—the Burgeson’s way.

Plus, with every heating and cooling service, we give you:

- Availability 7 days per week. Even if it's the 4th of July or Thanksgiving Day, we'll be there for you.

- Licensed & respectful techs. Our technicians take pride in their skill, attitude and workmanship.

- Peace of mind. We'll leave your home better than we found it—or we'll pay to clean it.

- 75+ years of experience: With 4.8 out of 5 stars on Google ⭐⭐⭐⭐⭐.